Physical Vapor Deposition

Physical vapor deposition (PVD) and especially evaporative deposition is a vacuum deposition technique that is used to deposit thin films by the condensation of a vaporized form of the material onto various surfaces (e.g., onto semiconductor wafers). The coating method involves a purely physical process such as high temperature vacuum evaporation rather than involving a chemical reaction at the surface to be coated as in chemical vapor deposition. More specifically the material to be deposited is heated to a high vapor pressure by electrically resistive heating in "low" vacuum.

Photo of two Thermal Evaporation Chambers that are settled in the Polymer Physics Laboratory. The thickness of the deposited film as well as the deposition rate is measured in real time by a quartz crystal microbalance (QCM).

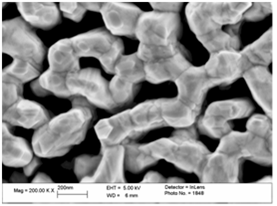

A perforated metal film disc on top of a 60μm thick porous dielectric (aluminum oxide). The silver film thickness is ~ 200 nm (plus a 50 nm gold passivation layer, so ~ 250 nm overall). The holes, arranged in a loosely hexagonal pattern, are about 200 nm in diameter and the mean distance between their centers is 300 nm. Around 30-40% of the surface area is covered by holes. The metals (silver and gold) are deposited by thermal evaporation.